Its difficult to look at the evidence of high technology in ancient Peru—the overwhelming tool and saw marks, perfect cut angles, flat surfaces and cube block removals, the perfectly fitting stones of similar rock but different strata—and then to look at the “historical” explanation of how these sites were created.

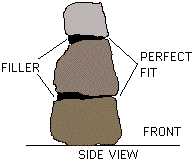

Historically we are told, by the archeologists, that the Inca (circa 1438-1533), took natural basalt, andesite, and diorite (all granite and 7-8 on the MOHS scale of hardness) and with copper and bronze chisels (3 on MOHS), river cobble and finger stones (4-5 on MOHS) they perfectly quarried, moved, cut and fit into place 50-150 ton blocks. Often times the quarries are more than 2 valleys away, meaning hauling tonnage up and over passes on little to no visible trails today. This feat is explained by using 2 techniques—the first being that the stones were quarried and then rolled down the mountain to the river below where they were then moved by water and gravel to their locations, often thousands of feet up yet another mountain. Then once in place they were wedged into place using trees and pullies to lift, mark and cut down the stones to their final fitting, so perfect to the pieces around them, a blade of grass cannot be inserted between the mortarless fixtures. Then through some force of heat, said to be at 1000+ degrees they were vitrified and heat treated into place. Not to mention we are also told that the stones only fit perfectly in the front and are back filled by mud and mortar. All within less than 100 years…

what makes this even scooping around the joints? bashing and sanding, in such even proportions?

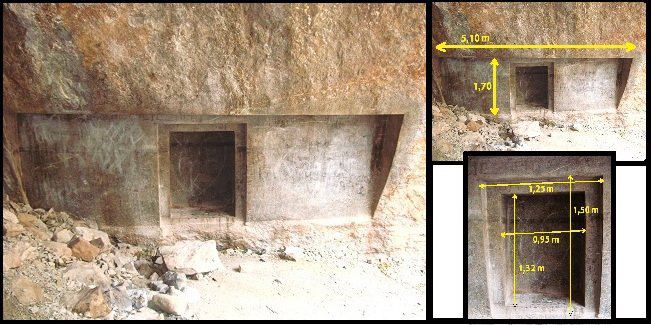

Yet even in these examples, we can see that there is no backfill and that these pieces are solid for 1-2 meters all the way through…

Please notice the lichen build up at these sites. Lichen grows in this strata at this elevation in this trophic level where 6 inches = 1500 years… some of these patches are off shoots on top of off shoots that are over 2 feet wide… so we have growth on top of growth on top of growth = 1500-10,000+ years of age (min/max) something to think about.

1) Reading through this account, there are many fundamental flaws in such speculation. The first being that archeologists are telling the tale here. None of which is a stone mason, a machinist, a geologist or an engineer, all of which have been to the sites in Peru and laughed at the accounts of how this was done and when.

Robert M. Schoch

Dr. Robert M. Schoch, a full-time faculty member at the College of General Studies at Boston University since 1984, earned his Ph.D. (1983) in Geology and Geophysics at Yale University. He also holds an M.S. and M.Phil. in Geology and Geophysics from Yale, as well as degrees in Anthropology (B.A.) and Geology (B.S.) from George Washington University. In 2014, Dr. Schoch was awarded the title of Honorary Professor of the Nikola Vaptsarov Naval Academy, Varna, Bulgaria.

Christopher Dunn

Christopher Dunn has an extensive background as a craftsman, starting his career as an indentured apprentice in his hometown of Manchester, England. Recruited by an aerospace manufacturing company, he immigrated to the United States in 1969. Over the past 49 years, Chris has worked at every level of high-tech manufacturing from machinist, toolmaker, programmer and operator of high-power industrial lasers, Project Engineer and Laser Operations Manager. For the past 16 year, he has served as Human Resource Director for a Midwest aerospace manufacturer.

Here are 2 to start the naming…

2) The second mix-match here is the MOHS scale of hardness. Since copper, bronze and river cobble are not even going to dent granite, let alone create a perfectly smooth surface with inset 90 degree angles, and tolerances to 1/100 of an inch, perfectly flat smooth. We are left with a colossal mystery here. Only diamond (found in Africa, and Asia) or tungsten carbide steel (a composite of the 20th century) could cut this type of stone to this type of precision—but neither exists in the “new world” at the time of the Inca. So how were the stones cut to such perfectly “machined” tolerances?

3) The third anomaly here is the moving of said tonnage from the quarry. As we are well above the natural tree line at both the quarry sites (where the stone type has been matched to the sites) and the ancient structure sites—the use of trees to move these stones and use of pullies to lift or lower them into place (without the knowledge of the wheel) is very weak at best. The other theory at play here is the rolling of the rocks from the quarry down the mountain to the river and then with water and gravel moving them to the sites 2000 feet up the next hill also holds no ground. Firstly the stones rolling from the quarry would break apart due to gravity and terrain alone and lets be honest and realistic, has anyone tried to push the weight of a cruise liner up a mountain with gravel and water?

Here is a comparison of what we would use today to move 1 stone weighing 150-500 tons max!! So as one can see it is NOT a matter of manpower but of technology and science as something this size is certainly NOT carrying these boulders from their quarry across the valley… and an object today weighing 150 tons (the cargo plane)

… just to give you an idea…

but here is the reality. the largest of these stones is 80tons (the one with the red dot)… it came from the quarry across the valley… they all did…

but here is the reality. the largest of these stones is 80tons (the one with the red dot)… it came from the quarry across the valley… they all did…

these stones are 2000 feet up and the quarry is across the valley and up the mountain… these stones are said to have been rolled from the quarry to the river below and moved with gravel and water to their perch… up the next hill?! unlikely.

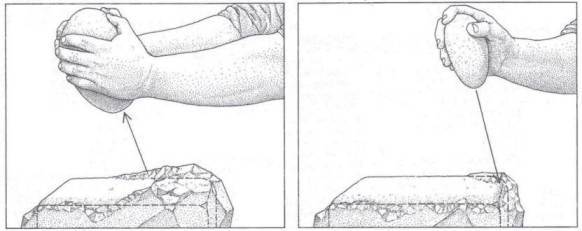

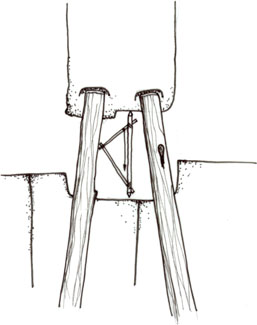

Here is an example of putting a 50 ton block into place, while using the alignment/measurement stick to position this correctly into place. Hard to believe that this method produces paper thin alignment perfection.

Having a hard time seeing how this tool can align 2 uneven surfaces with paper thin alignment perfection. Even CAD programs of today are not set to some of the surface tolerances found at these sites.

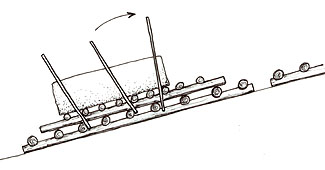

Here is a method for moving 80-100+ ton blocks from the quarry, on “roller” tracks. Again very hard to believe that the weight of a cruise liner is easily being moved down from a mountain quarry on fixed roller timber and guided with mere sticks. Under those weights, this is a roll-away disaster waiting to happen after the rollers are made into pulp juice. As we are way above the tree line, where are perfect poles coming from, and in excess strength to withstand such weights.

4) Which leads us to the final mystery here. The heat treating of the stones once they are in place. The rumor that the Inca vitrified their masonry is just wrong. First of all 1000 degrees F is the temperature that these sites’ tests have yielded. Thats plasma arch welding heat on a massive scale. Without the availability of trees, the rarified atmosphere of 11,000 – 13,000 feet and the serious lack of heat shielding and protective gear, I have a hard time believing that a native Inca (or previous cultures) could withstand the heat on the rim of a volcano to weld and vitrify acres of stone work at the same time. We cannot even do this today, so how was this done?

Here is an example of 1000 degrees external temperature due to fire exposure. It was achieved with “bushfire” simulation using continuous gas for 40 minutes and projected wind to reach (over 100kw/m2)… attainable, but certainly NOT natural. But something seen at the multiple acres of Saqsaywaman above Cusco. this site would have had to have burned for days naturally to achieve what chemicals reached in 40 minutes, begging the question of — how long would stone have to BURN to vitrify at 1000 degrees? and what naturally would do this (volcano? solar eruption? halocene commet? trees and shrubs burning? – all high octane speculation, but much more logical based on evidence than the “historical story” told here… and again… why would they burn the site?

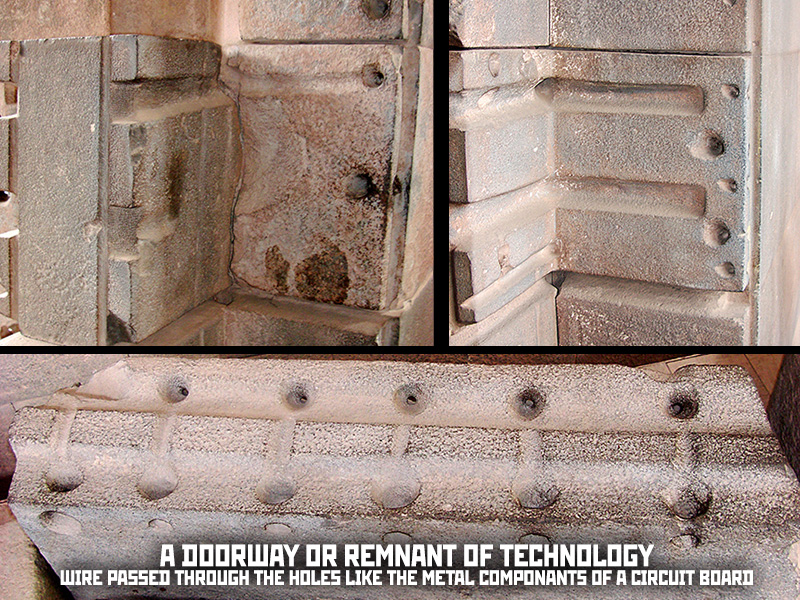

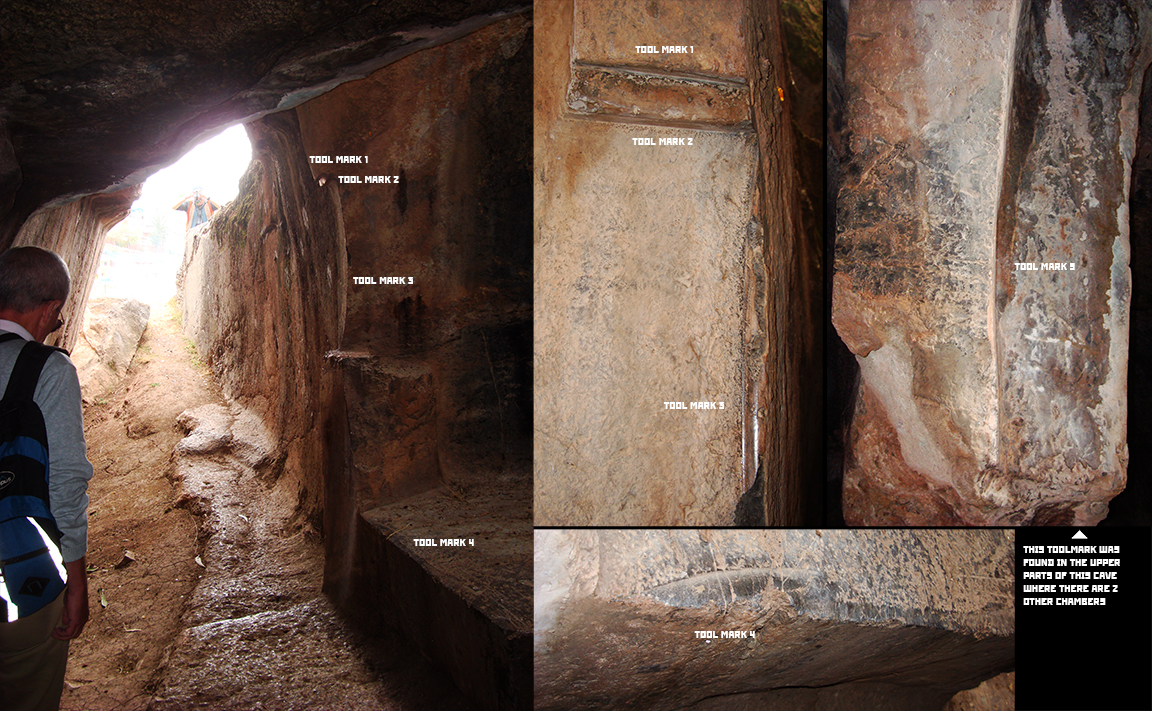

As you can see there are MANY holes in the historical explanation of how and when these sites were built. As engineers, masons, machinists, and geologists were not consulted in the historical evidence point of view—here is some of the evidence that they missed which shows machinery slipping while cutting, polishing in circular patterns at high rotation, perfect 90 degree angles and cube removals, flat tolerance unattainable by bashing out with stone.

Not done through rotation, part of the crystal in the rock has been dragged through in a straight line at high speed

As you can see from these examples – these are NOT examples of stone or copper or bronze based tool work, but precision machinery and tooling… We still do not know how, who or when these structures were created. Based on spoken history and the hidden history the Jesuits recorded, the Inca did not infact build any of the sites we see, they inherited and fixed them up with shoddy stone masonry and an amazing agricultural sense, but lacked the sophistication of the building styles at most of the sites seen.